Eagle Group® Auditing

Eagle Group® Auditing

the right choice for trusted, expert Management Systems audits.

Eagle Group® experts are ready with customized solutions, continuous support opportunities, and a track record to drive improvements for your Management Systems audits. We specialize in Internal audits, Product Audits, Supply Chain Audits, Compliance and other audits.

Our auditors have years of field experience and knowledge to uncover and address non-conformances to recognized Management Systems standards. Ultimately, there is nothing better for your team than having the Eagle Group® edge, knowing you are prepared, confident, and ready for the Registrar audit.

Management System Audits

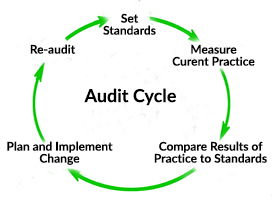

Internal Audit … hire Eagle Group® to conduct your ISO-based Management Systems Internal Audit. Know before you go, you comply with the audit requirements for a successful Registrar audit. Nobody likes surprises, we make sure you know what to expect using our outline-scope of Internal Audit cycle activities.

What

are the

benefits

?

The Auditor will conduct:

Final Review Audit, we come to your facility and assess your documented Management System against each element of the Standard, and confirm each “shall statement” of the standard has been addressed. Then, we use your Corrective Action System to raise non-conformances and provide recommendations for the implementation of corrective actions, prior to registration. Based on the findings of the final review audit, the certification body will make a decision regarding whether to certify the organization to the ISO standard. If all requirements are met, the organization will receive ISO certification.

Product Audits

Eagle Group® conducts audits for clients to verify that Customers / 3rd Party Tollers / Formulators / Suppliers are in compliance with agreed-to requirements. During a product audit, trained auditors examine processes, documentation, and product samples to verify compliance with selected standards. This comprehensive approach helps organizations identify potential non-conformities, improve product quality, and enhance customer satisfaction by ensuring that their products meet internationally recognized benchmarks for safety, performance, and consistency. These audits are often employed to meet Responsible Care® type Management Systems requirements. After the audit, a confidential summary report will be produced to your specifications; and If requested, we will provide additional services such as ranking of the organization. The results of these audits play a crucial role in maintaining product quality and ultimately fostering trust with customers and stakeholders.

SupplY CHAIN Audits

Many Management Systems require qualification and ongoing performance reviews of your supply chain. Get the value-added solution with an Eagle Group® audit of your critical suppliers.

Automotive Management Systems – IATF 16949 requires you to develop your suppliers to the IATF 16949 and ISO 9001 requirements. Most of the Original Equipment Manufacturers (OEM) and their Tier One suppliers allow you to audit these suppliers in lieu of requiring them to be registered.

Note: There are a few OEMs and Tier 1 suppliers that may not allow you to subcontract these audits (such as Chrysler).

Environmental and Responsible Management Systems – some Management Systems such as Responsible Care® require the supply chain to act in a responsible manner. The American Chemistry Council’s Responsible Care® Management Systems (such as RC14001) require the registered organization to: “qualify and periodically review carriers, suppliers, distributors, customers, contractors and third-party providers based on Responsible Care® or other health, safety, security and environmental performance criteria.” Other Management Systems, such as the Canadian Responsible Care® program, require Transportation Carrier Assessments every two years.

Quality Management Systems play a critical role in ensuring the efficiency and reliability of the supply chain processes within an organization. These systems are designed to monitor, control, and improve the quality of products or services throughout the entire supply chain, from raw material suppliers to end customers. They involve the implementation of various tools, methodologies, and best practices to track and manage quality at each stage of the supply chain. This includes supplier evaluations, quality inspections, performance metrics, and corrective actions when deviations are detected.

Eagle Group® will conduct the periodic evaluation of your supplier’s Compliance System, such as those for DOT and OSHA requirements.

COMPLIANCE & OTHER AUDITS

Compliance Audits

Environmental Compliance Auditing – to assist you in your “commitment to compliance” for maintaining an Environmental Management System, such as ISO 14001, RC14001 and Responsible Care® Management System. Eagle Group® will conduct the periodic evaluation of your Compliance System. Audit Results are reported per ASTM E2107 Standard Practice for Environmental Regulatory Compliance Audits.

Occupational Health and Safety Compliance Auditing – helps you maintain proactive measures of performance to monitor compliance with applicable legislation and regulatory requirements for an OH&S Management System, such as ISO 45001, RC14001 and Responsible Care® Management System. Eagle Group® will conduct the periodic evaluation of your Compliance System. Audit results are reported per ASTM E2107 Standard Practice for Environmental Regulatory Compliance Audits.

Note: There is no current standard for OH&S reporting so we use the environmental format.

Other Audits

International Traffic in Arms Regulations (ITAR) – for organizations that are involved in the exporting of any defense products, services, or related technical data this set of export control laws are designed to prevent unauthorized foreign nationals from procuring accessing physical materials or technical data related to defense and military technologies is restricted.

Security Vulnerability Assessments (SVA) – a vulnerability assessment of your security weaknesses such as in information systems, transportation routes, of physical facilities. It evaluates if the system/organization is susceptible to any known vulnerabilities, assigns severity levels to those vulnerabilities, and recommends remediation or mitigation, if and whenever needed. For instance, many chemical handling organizations are subject to the federal requirement “Chemical Facility Anti-Terrorism Standards (CFATS)” which requires.

Proposition 65 – is officially known as the Safe Drinking Water and Toxic Enforcement Act of 1986. Designed to protect California’s drinking water sources from being contaminated with chemicals known to cause cancer, birth defects or other reproductive harm, and requires businesses to inform Californians about exposures to such chemicals. These requirements are extended to out of state manufacturers and requires the organization to provide a consumer warning and applies regardless of whether a business is located in California or out-of-state, as long as its products cause exposures to individuals in California. https://www.p65warnings.ca.gov/